Infrastructure tunnels are laid at a depth of 3-5 m underground, where there is high humidity, contact with groundwater and an aggressive environment is possible. Cable runs tens of meters long require trays with high corrosion resistance and overheating protection.

2. Materials and coatings

Manufacturers such as the Bonn Group and Emerald Steel Industries offer stainless steel or FRP (GRP) cable trays for applications where chemical resistance and long—term durability are required.

FRP ladder trays (GRP cable ladder) from the Bonn Group are highly resistant to corrosion and UV, and their service life reaches 20-30 years.

3. Construction and mechanical parameters

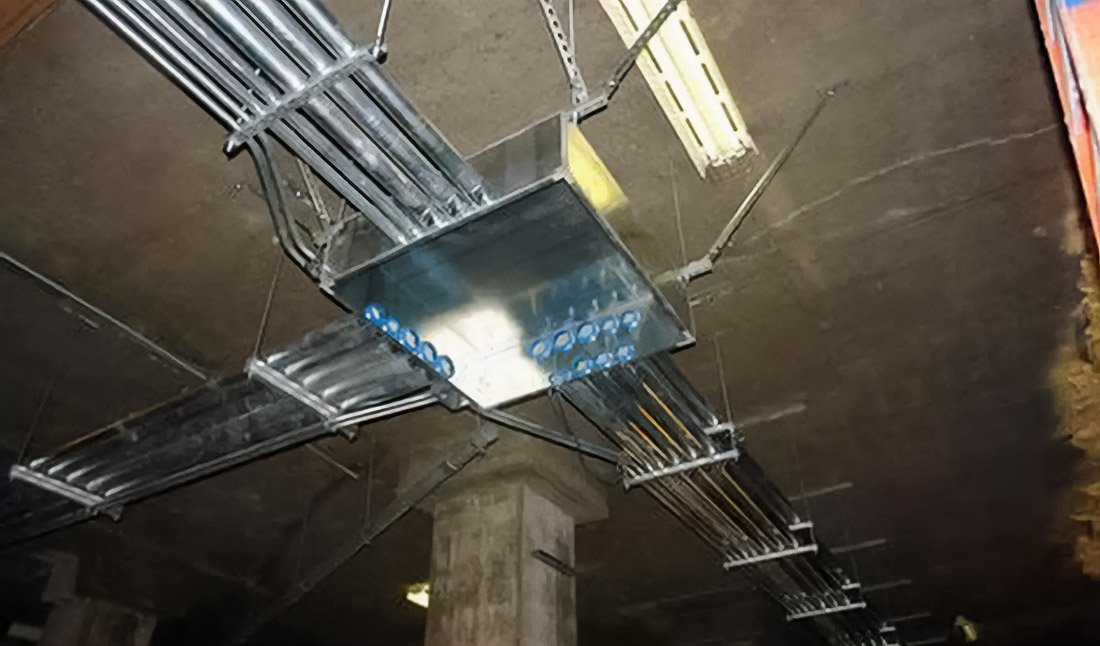

Underground installation requires a reinforced load-bearing profile: designed for uniform load, the ability to withstand up to 100 kg/m with a span of up to 1 m and about 50 kg/m with a span of 2 m, as in a similar design practice in the UAE

Many cable tray suppliers in uae equip the trays with rigid side flanges, reinforced ribs and accessories — T‑joints, crosspieces and couplings — to adapt the routes in tunnels.

4. Compliance with standards

The companies strictly follow international standards: BS EN 61537 / IEC 61537, as well as ISO 9001. This is a prerequisite for supplies to large infrastructure facilities in Abu Dhabi and participation in projects of DEWA and water resource corporations

5. Reviews and real projects

— Delta Cable Trails (part of TRANSCON Global Group with a plant in Ajman) supplies solutions for subways, airports and substations with an emphasis on lightness, corrosion protection and ease of installation

— West Port Cable Tray offers comprehensive engineering services, including designing the ascents and turns of the route in tunnels underground — fault tolerance and channel safety are guaranteed through precise fitting of elements and support of design teams

6. Engineering support and maintenance

Manufacturers, including Emerald Steel Industries and Bonn Group, provide project support services: AutoCAD and PDMS‑route modelling, engineering calculations, selection of materials for load and anti-corrosion characteristics

7. Economic efficiency

The choice of AISI 316 or FRP stainless steel allows you to minimize maintenance costs, reduce the frequency of tray replacement and increase the operational reliability of tunnels. Although the initial investment is higher, long service life and compliance with standards pay off due to safety and ease of operation.

Conclusion

Cable tray manufacturers in the UAE, including Bonn Group, Emerald Steel Industries, Delta and West Port, are adapting structures to the requirements of Abu Dhabi’s underground tunnels, using corrosion‑resistant materials, combination with FRP technologies, engineering support and compliance with international standards.

The role of cable tray suppliers in uae as an integrator of solutions with reliability, modularity and durability is critical for modern infrastructure facilities in the UAE capital.

Soccer lover, doer, music blogger, Swiss design-head and proud pixelpusher. Doing at the junction of art and programing to craft delightful brand experiences. I’m a designer and this is my work.